Mechanical Engineering has been evolving itself with its newer technologies; one of its kinds is 3D printing.

3D printing is also called additive manufacturing. This term accurately describes how this technology works to create objects. “Additive” refers to the successive addition of thin layers between 16 to 180 microns or more to create an object. In fact, all 3D printing technologies are similar, as they construct an object layer by layer to create complex shapes.

Why 3D printing?

This is where 3D printing becomes a very useful tool for industrial applications: Industries can manufacture parts that are lighter, heat-resistant, stronger; and with less parts industries can build the same products: for one of their jet engines. GE engineers reduced 855 separate parts to just 12, dramatically simplifying the assembly process.

With additive manufacturing, complexity is free: Industries can build a geometrically very complex object as easily as a simpler one. But at the same time, additive manufacturing helps reduce complexity by giving us fewer parts to assemble. In the Industry 4.0 revolution, additive manufacturing plays a major role; it will help upgrade existing economies of scale and make micro-factories economically efficient; and it is already helping to reshape global supply chains, expanding local networks.

3D printing makes it possible to use new materials and in turn, stimulates advancement in materials science to create new materials that are better suited to the additive process. Aided by AI and enhanced by 3D printing, new material discoveries are expected to accelerate in 2025.

How it Works?

There are 3 main steps in 3D printing.

When you design a 3D file of the object you want to print, the first step is the preparation just before printing. It is possible to build this 3D file using CAD software, a 3D scanner or simply download it from an online marketplace. You will proceed to the second phase once you have verified that your 3D file is ready to be printed.

The actual printing process is the second stage. First, you need to select the material better accomplishes the particular properties needed for your object. In 3D printing, the range of materials used is very broad. Plastics, ceramics, resins, metals, sand, textiles, biomaterials, glass, food, even lunar dusts are included.

The finishing process is the third stage. Specific skills and materials are required for this move. It can also not be immediately used or shipped when the item is first printed until it has been sanded, lacquered or painted to complete it as intended.

Applications of 3D printing

In china, 3D printers are used construct houses. Industries started to prefer 3D printers due to its precision manufacturing and shorter lead times over traditional manufacturing process such as casting forming etc. NASA has invested in the 3D printing technology in the hope that in future astronauts will be able to print their food whilst in space. Complex shaped products can be easily manufactured by 3D printing technology. Food industry use 3D printers to manufacture food products such as chocolate &pasta. Research and Development team of food industries are concentrating on 3D printing technology to maintain the nutrition balance of 3D printed food stuffs to tackle the health problems such as diabetes and obesity.

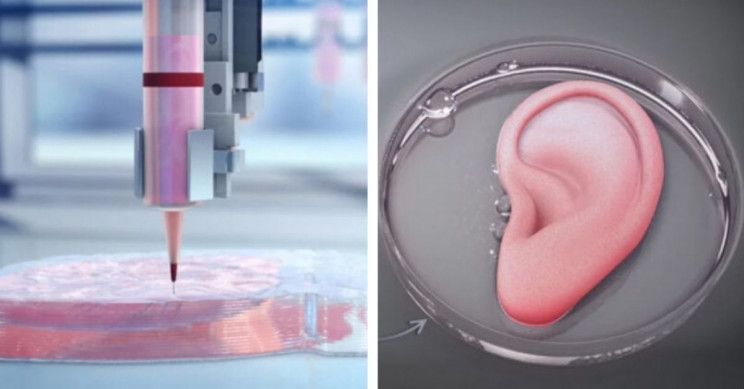

The failed human organs are replaced by 3D printed organs. The new drugs developed can be easily tested on 3D printing organs such as kidney so that it can avoid the risk of testing directly on human. Elastic bones which are printed by the 3D printers were successfully tested on animals.

(Source- https://interestingengineering.com/the-science-fiction-world-of-3d-printed-organs)

Person who lost of eye sight can now replace the faulty eye with 3D printed bionic eye. ‘Bionic eyes are usually thoughts of science fiction, but now researchers are closer ever using a multi maternal 3D printers ‘-research article by co-author Michael C. Mc Alpine, PhD, professor, Department of Mechanical Engineering, University of Minnesta. Bionic is an array of semi conductor photo detectors made of polymers, printed on glass hemisphere.

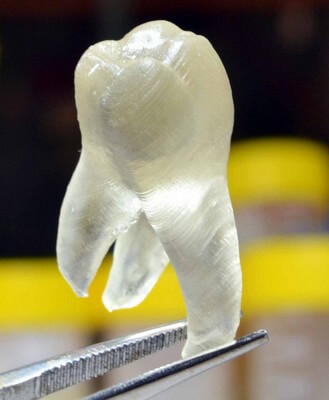

Researchers in Groningen from Netherland developed 3D printed tooth but one that kills bacteria. The tooth material is made from conventional artificial tooth resins combined with positively-charged quaternary ammonium ions. When the material encounters the negatively-charged membranes of bacteria it kills the microbes.

Medical field is concentrating to develop implantable artificial ovaries for the patients lost their fertility due to Turner syndrome and during cancer treatments such as chemotherapy and radiotherapy. In 2017, the research team achieved a huge milestone when it 3D printed an artificial ovary and implanted it into a sterile mouse. Researchers are one step behind in alternative to women whose ovaries have been damaged.

(Source – https://www.mdlinx.com/article/7-amazing-body-parts-that-can-now-be-3d-printed/lfc-2668)

3D-Printing technology did an abracadabra in the field of health care, construction, food processing, Art and jewellery, Medical Science, Automobile and aerospace. It’s very difficult to compress the wide range applications of 3D printing Technology in single article. This article tries to be an eye opener for the budding graduates who endeavor to step their footsteps in the stream of 3D printing technology.

The growth of various fields is safely in the hands of 3D printing technology.

By

Harshavardhan K P (9600819095)

Assistant Professor

Deparment of Mechanical Engineering

Karpagam Institute of Technology