About

The Department of Mechanical Engineering has been a part of Karpagam Institute of Technology (KIT), one of the top Engineering Institutes in Tamil Nadu, offering an undergraduate degree program (B.E. Mechanical Engineering) since 2009. The Department of Mechanical Engineering is fully committed to creating engineering talent for the Industry and the Community.

It has highly qualified, experienced and devoted faculty members as well as a dynamic environment for research activities headed by Professors with Ph.D. degree from prestigious Universities. At the moment, six faculty members are actively involved in research to get their Doctoral degree.

The Department has built state of the art facilities to spread emerging advancements by including software for cutting-edge technologies in the fields of Computer Aided Design and Manufacturing. The projects and hands-on training activities are intended to instill an entrepreneurial mindset in students and encourage them to start their own enterprises.

To create innovative, entrepreneurial and socially committed Mechanical Engineers to meet industrial demands.

- Developing core competency in Mechanical Engineering through state-of-the-art facilities and effective teaching practices.

- Encouraging and nurturing research potential and promoting entrepreneurial endeavors.

- Instilling social and ethical values through extension activities.

- PEO1: Pursue career in core/multidisciplinary organizations worldwide with opportunities for advancement.

- PEO2: Enhance technical proficiency and research capabilities for innovation and entrepreneurship.

- PEO3: Emerge with leadership skills and contribute to societal progress through ethical Engineering practices.

- PO1: Engineering knowledge: Apply the knowledge of mathematics, science, engineering fundamentals, and an engineering specialization to the solution of complex engineering problems.

- PO2: Problem Analysis: Identify, formulate, review research literature, and analyze complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and engineering sciences.

- PO3: Design/development of solutions: Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health and safety, and the cultural, societal, and environmental considerations.

- PO4: Conduct investigations of complex problems: Use research-based knowledge and research methods including design of experiments, analysis and interpretation of data, and synthesis of the information to provide valid conclusions.

- PO5: Modern tool usage: Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modeling to complex engineering activities with an understanding of the limitations.

- PO6: The engineer and society: Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice.

- PO7: Environment and sustainability: Understand the impact of the professional engineering solutions in societal and environmental contexts, and demonstrate the knowledge of, and need for sustainable development.

- PO8: Ethics: Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice.

- PO9: Individual and team work: Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings.

- PO10: Communication: Communicate effectively on complex engineering activities with the engineering community and with society at large, such as, being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions.

- PO11: Project management and finance: Demonstrate knowledge and understanding of the engineering and management principles and apply these to one‘s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments.

- PO12: Life-long learning: Recognize the need for, and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change.

- PSO1: Acquire Knowledge in product design and development with computer aided tools ensuring modern manufacturing practices.

- PSO2: Apply analytical skills gained to solve complex Engineering problems related to fields of production, thermal and fluid mechanics.

- PSO3: Develop multidisciplinary projects with excellence in Engineering analysis and managerial skills in consideration for environment and social impacts.

- Engineering Practices Laboratory (Welding, Sheet Metal, Foundry and Fitting Shop)

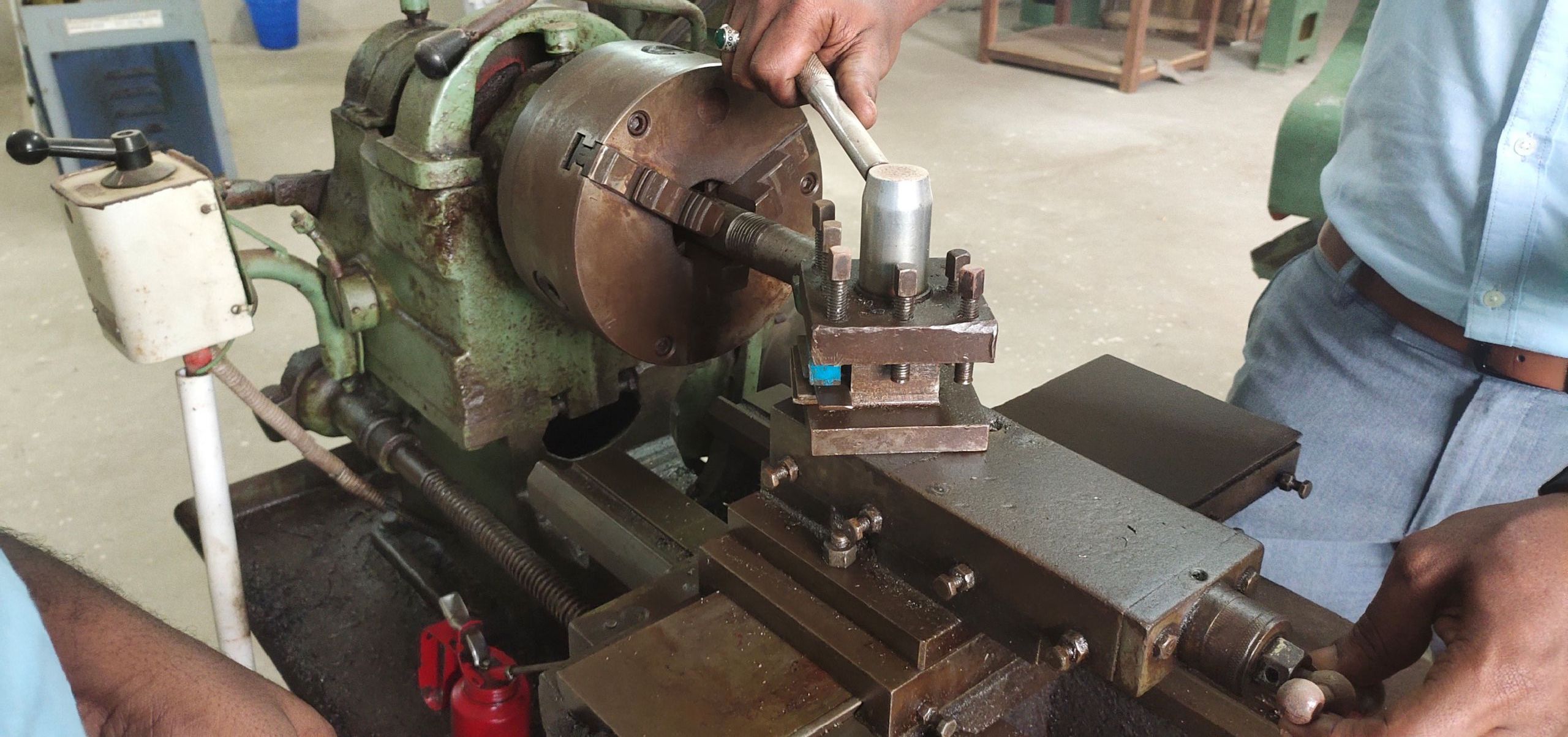

- Machine Shop (Manufacturing Technology Lab I & II)

- Dynamics Laboratory

- Strength of Materials Laboratory

- Thermal Engineering Laboratory

- Heat Power Laboratory

- Mechatronics Laboratory

- Metrology and Measurements Laboratory

- Fluid Mechanics and Machinery Laboratory

- CAD/CAM Laboratory

- Simulation and Analysis Laboratory

- Tamil Nadu State Transport Corporation Depot, Pollachi.

- Ashok Leyland, Chennai.

- ELTEX super casting, Coimbatore.

- Texmo Industries, Coimbatore.

- ELGI Rubber Company Limited, Coimbatore.

- Ford, Chennai.

- Hyundai motors, Chennai.

- Larsen & Toubro Limited, Coimbatore.

- BMW, Chennai.

- TVS, Chennai.

- Toyota, Chennai.

- BHEL, Trichy.

- SPIC, Tuticorin.

- SAIL, Salem.

- NLC, Neyveli.

- Department is permanently Affiliated to Anna University, Chennai since 2018 for its well known Infrastructure and Facilities

- More experienced & highly motivated faculty members with good academics

- Following Outcome based Teaching and Learning process

- Department has Modernized Laboratories

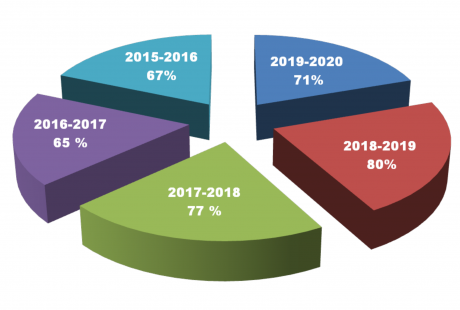

- Excellent Placement record

- Department has adequate Student-Teacher ratio as per AICTE norms

- Department frequently conducts Value Added Courses

- Department has strong and active Alumni forum-REWIND

- Possessing SAE Vehicle Design Lab for SUPRA and BAJA

- Department provides PMKVY- CNC Training to Rural Youths

- Department has 3D Printing facility for Hands on Training of Students

- Department provides Spoken Tutorial Courses of IIT Bombay

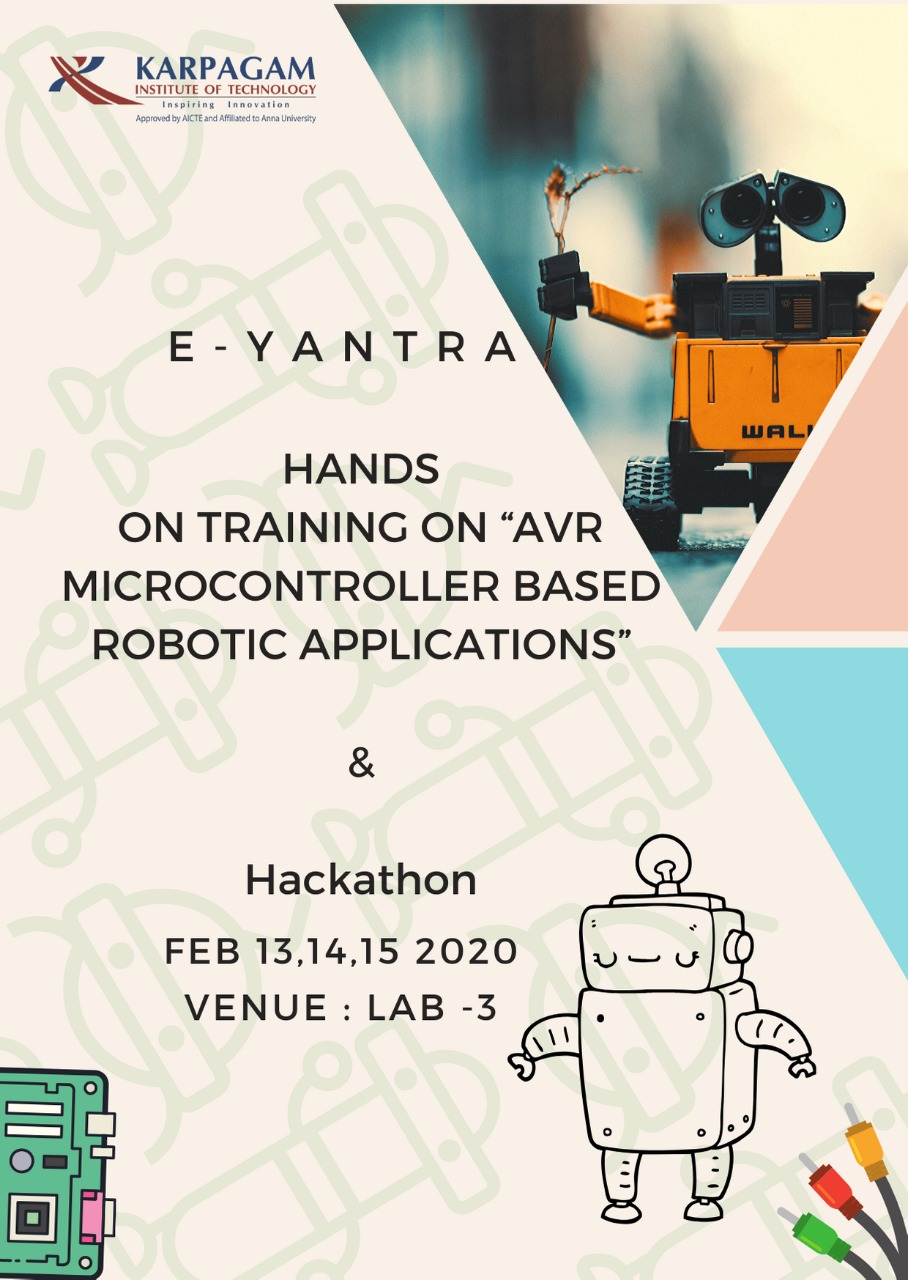

- Department has active E Yantra Lab (Supported by MHRD and IIT Bombay)

- Department offers In-Plant Training and Industrial Visits to students

- Department organizes Entrepreneur Awareness Camp (Supported by MSME)

|

|

|

|

|

|

|

|

|

|

|

|

|

Vasumathi Castings |

| Academic Year | Project Details | Students | Industry |

| 2019-20 | Methods in improving the efficiency of Lignite fired boiler in Thermal Power Station | M.Mugilan |  |

| M.Revanth | |||

| K.S.Selva Muthu Kumaran | |||

| J.Sivakumar | |||

| 2019-20 | Performance analysis of Steam Turbine | M.Abinesh |  |

| R.Balraj | |||

| K.Kaviraj | |||

| M.Manoj Prabhakar | |||

| 2017-18 | Replacement of Jig for Belt Idlers in specialized Mining equipments | K.M.Balavignesh |  |

| M.Bhaveen | |||

| M.Gokulnath | |||

| A.Hariharan | |||

| 2017-18 | Experimental Investigation on Solar Parabolic trough collector | S.N.Kabilan |  |

| S.Mouleeswaran | |||

| S.Jayaprakash | |||

| M.Ananda Kumar | |||

| 2017-18 | Heat rate performance study in Thermal Power Plant | B.Cibi |  |

| J.Dhanasekar | |||

| R.Karthick | |||

| S.Gokul Raja | |||

| 2017-18 | Performance analysis on Heating Ventilation Air Conditioning (HVAC) system | S.Praveenkumar |  |

| S.Ramkumar | |||

| K.Saravanan | |||

| G.Sathish kumar | |||

| 2017-18 | Study and Analysis to increase the life of Full Deflector plate in Mill Rotor | M.Prakesh |  |

| T.Ragunathan | |||

| C.Sasidharan | |||

| K.Yuva bharathi | |||

| 2017-18 | Design and development of a 3D Printer | K.Pavithra |  |

| C.Sarath kumar | |||

| R.Sudhan | |||

| M.Venkatragavan | |||

| 2016-17 | Productivity Enhancement of CNC Lathe-shop by adopting Cellular Layout | M.Karthik |  |

| S.Karthik | |||

| E.Gowtham |